Cast floor finish - Cast floor coating - RAL 7023

PUR Flexo cast floor A+B 7023 23.5 KG

PUH16050047

In stock

Is a 2-component solvent-free PU casting coating for self-levelling of floors in living areas, commercial floors or trailers. Extremely resistant against diluted acids and alkalis.

Available in 23,5 kg packaging.

Available in different RAL colours.

Standard available in RAL 7000.

Other Ral colours on order.

Available in different RAL colours.

Standard available in RAL 7000.

Other Ral colours on order.

€340.17 / set

Applications

As a self-levelling casting coating for floors consisting of wood, concrete (provided a primer is used). Ideal coating for lorries used in meat and food transport, as it is physiologically neutral after curing. If the floor has to be anti-slip, a carbide granule can be sprinkled in the top layer of Flexodur Topcoat.

Do not use for transpallet applications.

Do not use for transpallet applications.

Usage

Follow our handy step-by-step plan to lay a self-levelling floor:

STEP 1: Preparing your substrateIt is important to clean and prepare the surface properly before laying a PU floor.

• Concrete must have dried for at least 28 days and be free of grease, dirt, dust and nitrogen deposits.

• Wood should be sanded with 40 grit paper.

• The temperature of the surface should be at least 16°C.

• The ideal application temperature is between 18°C and 23°C.

• Work on a flat subfloor.

• Repair any damage beforehand.

• Remove paint or glue residues.

STEP 2: Applying a primer layer

Start with the application of the Epoxy Primer Fast. The substrate may be slightly moist.

CAUTION! Never use this primer on bitumen, only on porous substrates such as wood, metal and concrete.

STEP 3: Applying a cast floor

First thoroughly mix the A-component. Then thoroughly mix both components in a 5:1 weight ratio. The mixing is preferably done with a screw mixer mounted on a drilling machine. Prepare the tools so that you can start after mixing.

• Processing time: 25 to 40 min. at 20° C

• Minimum processing temperature: 18° C

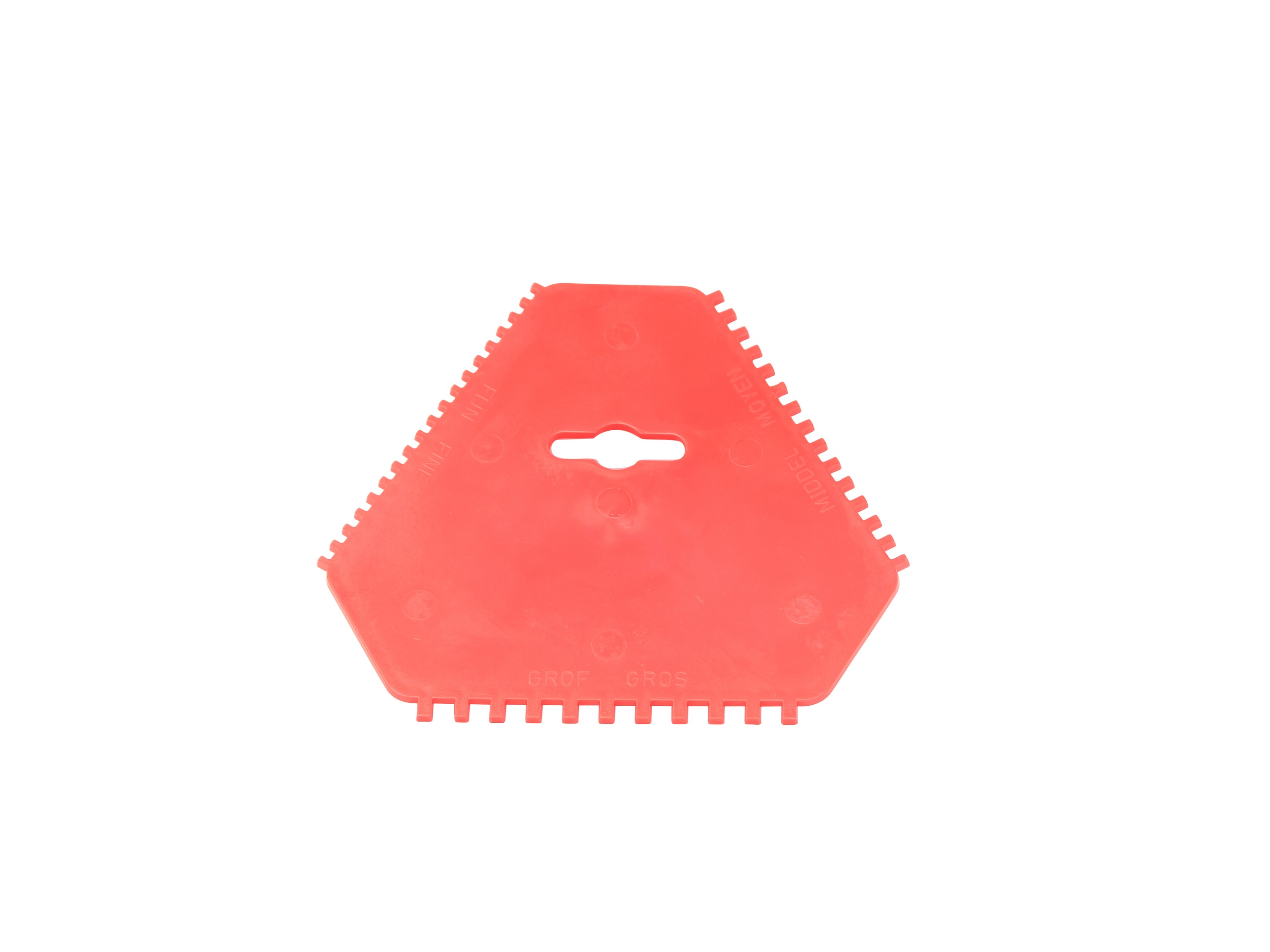

• Pour a scraper coat and bleed with a spiked roller

• Allow this layer to dry completely and sand with coarse sandpaper (P80).

• Remove dust and dirt before further work

• Then pour a second layer and de-aerate with a spine roller

STEP 4: Finishing

There are various types of finishing layers that you can apply to your cast floor.

1. High-gloss finish: Use Urki Voc for this.

2. Satin finishing: for this you use Flexo PUR Top ZG

3. Matt finishing: use Acrylic 1K Topcoat

This final coat provides additional UV protection and increases resistance to abrasion. The different types are available as standard in a number of RAL colours.