Polyester topcoat 5 kg - Smooth finish for pools - RAL 9010

LT40SB 9010 5 KG

UPH01100221

Deliverable in 1-5 working days

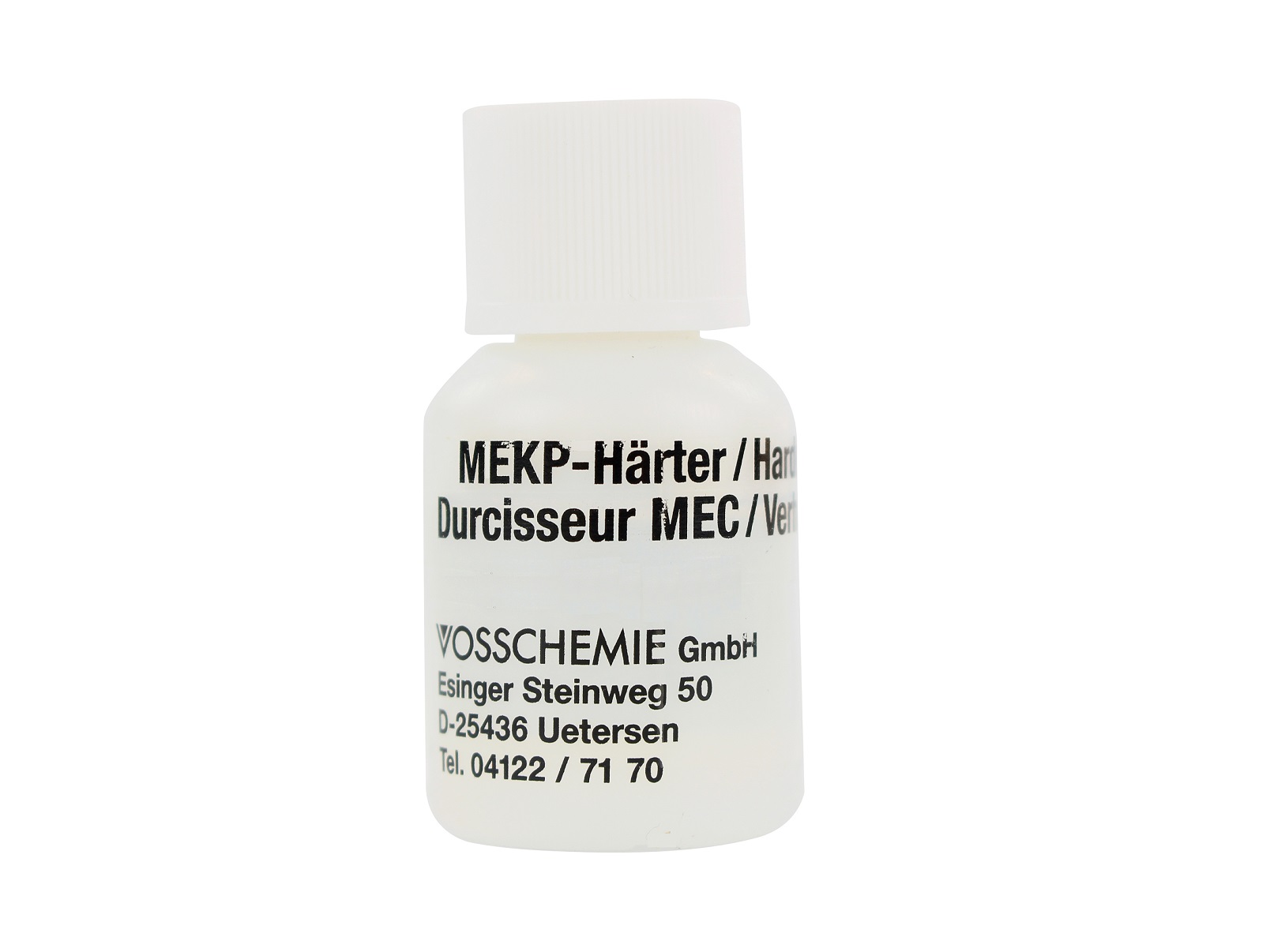

Is a 2-component, pre-accelerated topcoat based on neopenthylglycol-terephthalic acid that after curing has good chemical, water and UV resistant properties, at application temperatures of water up to 30°C. Resistant to chlorinated water and hydrogen peroxide (with normal swimming pool use). Available in 1, 5, 20 and 225 kg packs (colourless) and in 5, 10 and 20 kg packs pre-coloured.Due to the unique composition with terephthalic acid, this final coat has an extremely high resistance to osmosis and symptoms of black spots in old polyester layers.

€126.36 / st

Applications

Adhesive-free final coat (topcoat) for a polyester laminate as protective layer and finish.Can be coloured with a maximum addition of approx. 5-10% UP pigment. Spraying is possible with the addition of approx. 5% styrene. Has its application in amongst others swimming pools, containers and tanks as well as elements for the construction industry. Topcoat LT 40 SB is always processed in combination with precoat T 40 BT for a good chemical and water resistance with a maximum water temperature of 30°C. Recent tests have shown that the use of salt solutions at elevated temperatures can cause black spots in the final coat. The use of this topcoat LT40SB is therefore not recommended.Tip: some colour pigments discolour faster than others! For example: dark grey will fade.