Collect & go with online advice

Largest selection of cold curing plastics

55 years of experience

Order before 12:00, <48 hour delivery

Applications of reinforcement materials

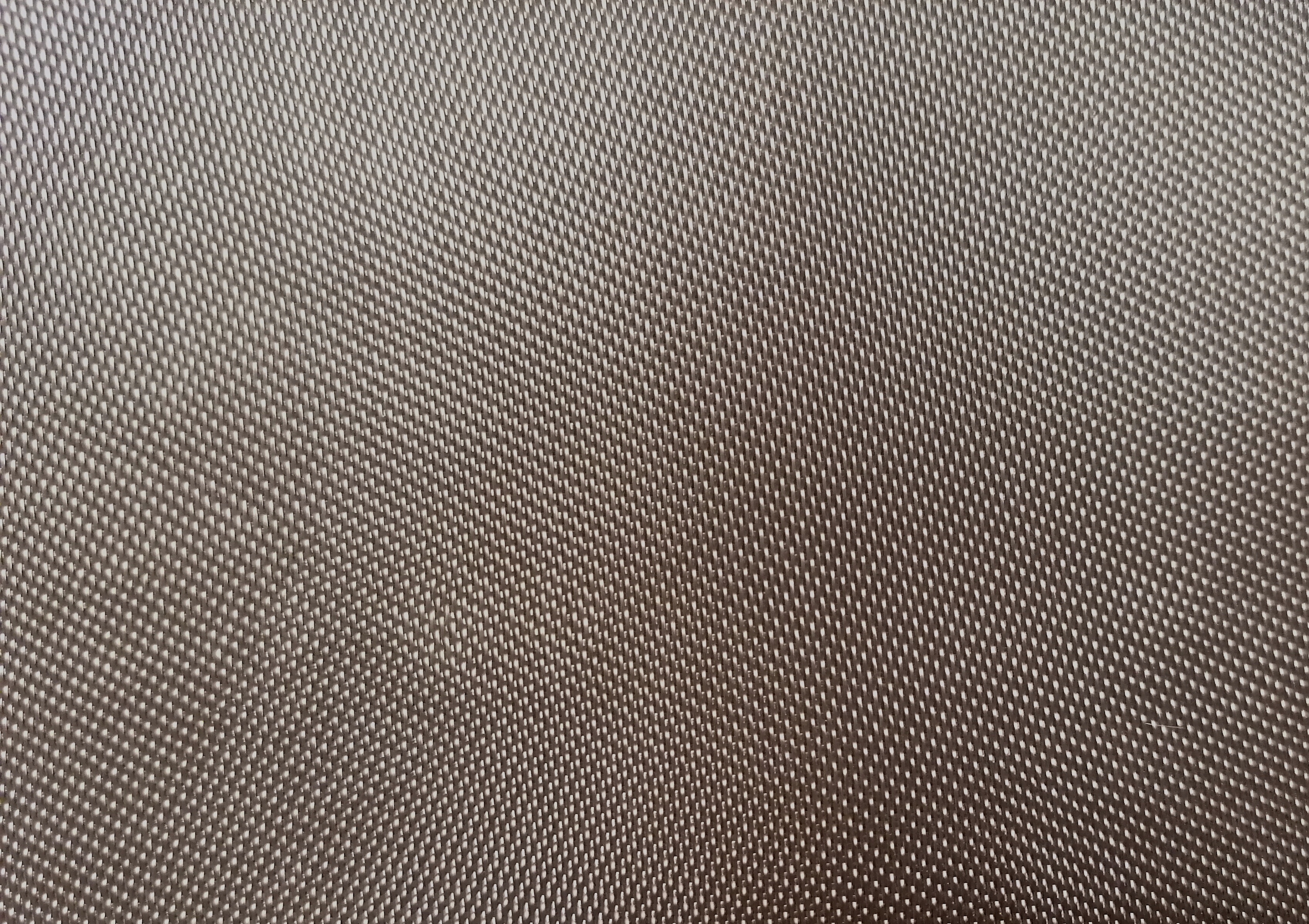

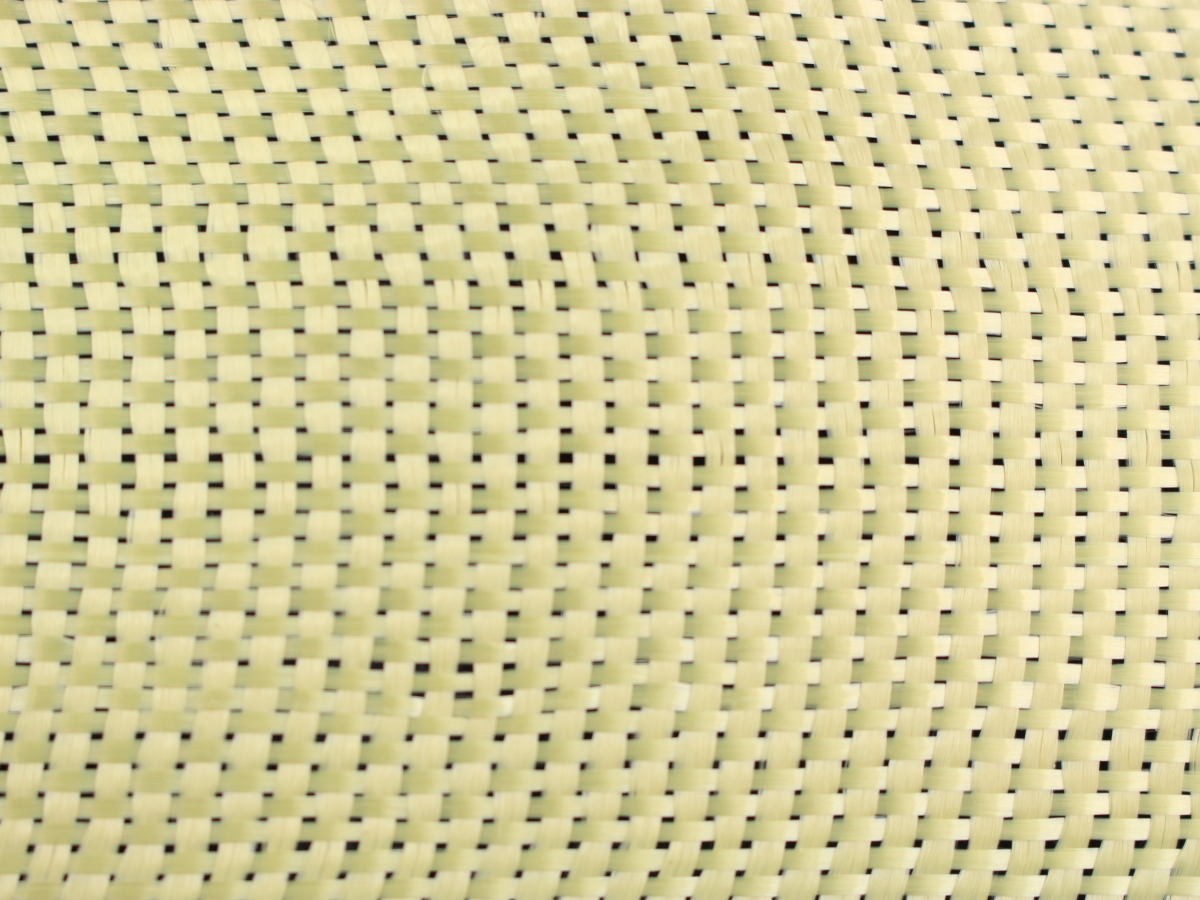

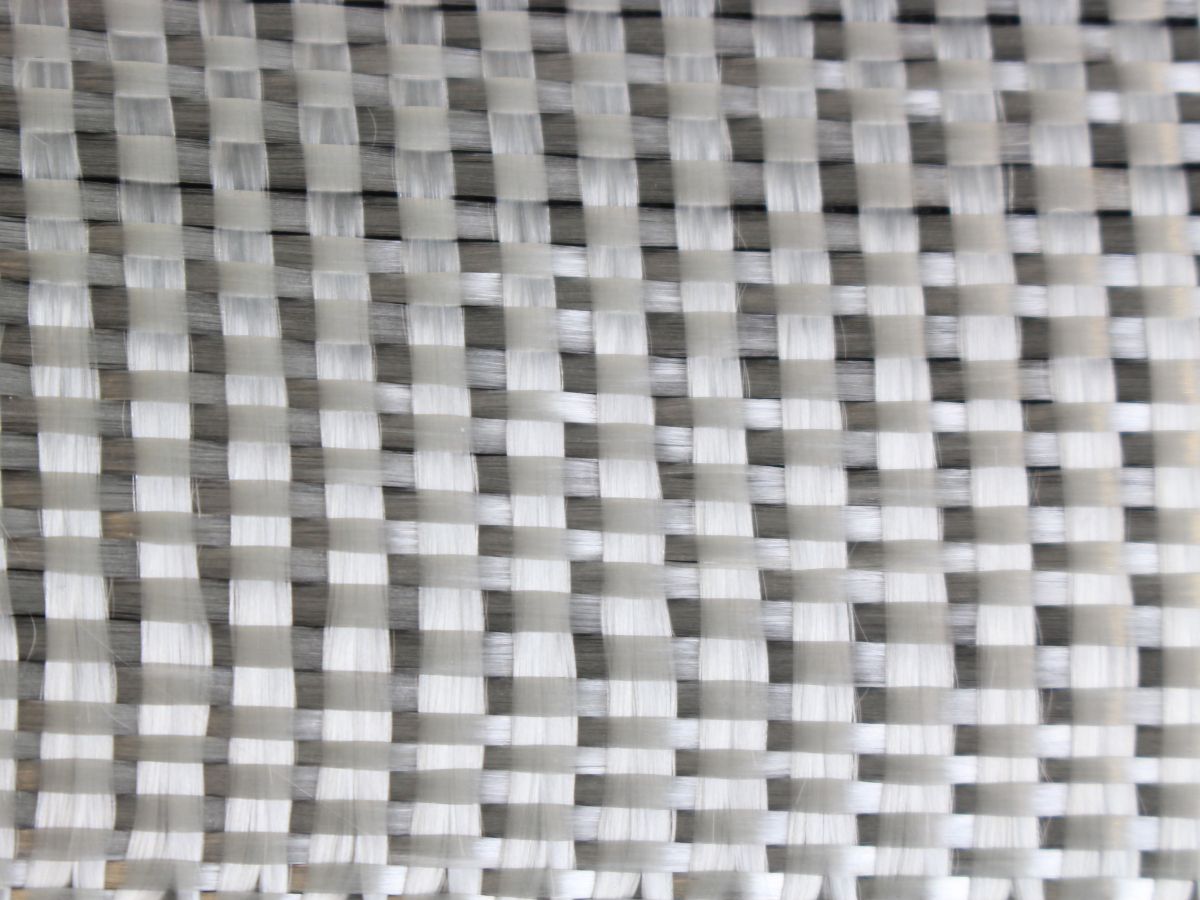

In the composites industry, glass fibre is often used as reinforcement material. The woven structures of glass fabric provide a more durable structure in combination with polyester or epoxy resin. The combination of polyester and glass fibre is also frequently used by private individuals, for example when repairing the hull of a boat.

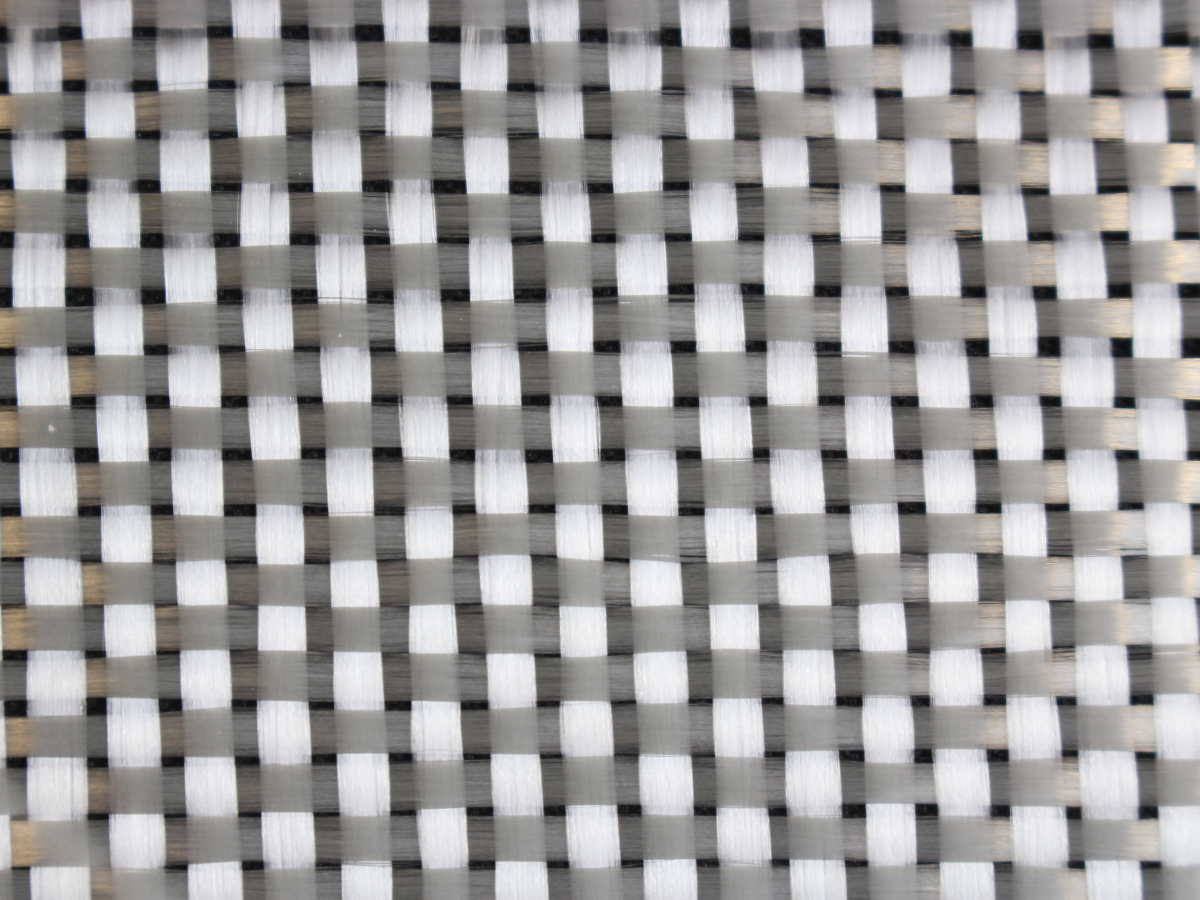

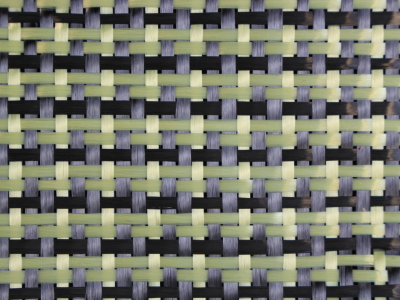

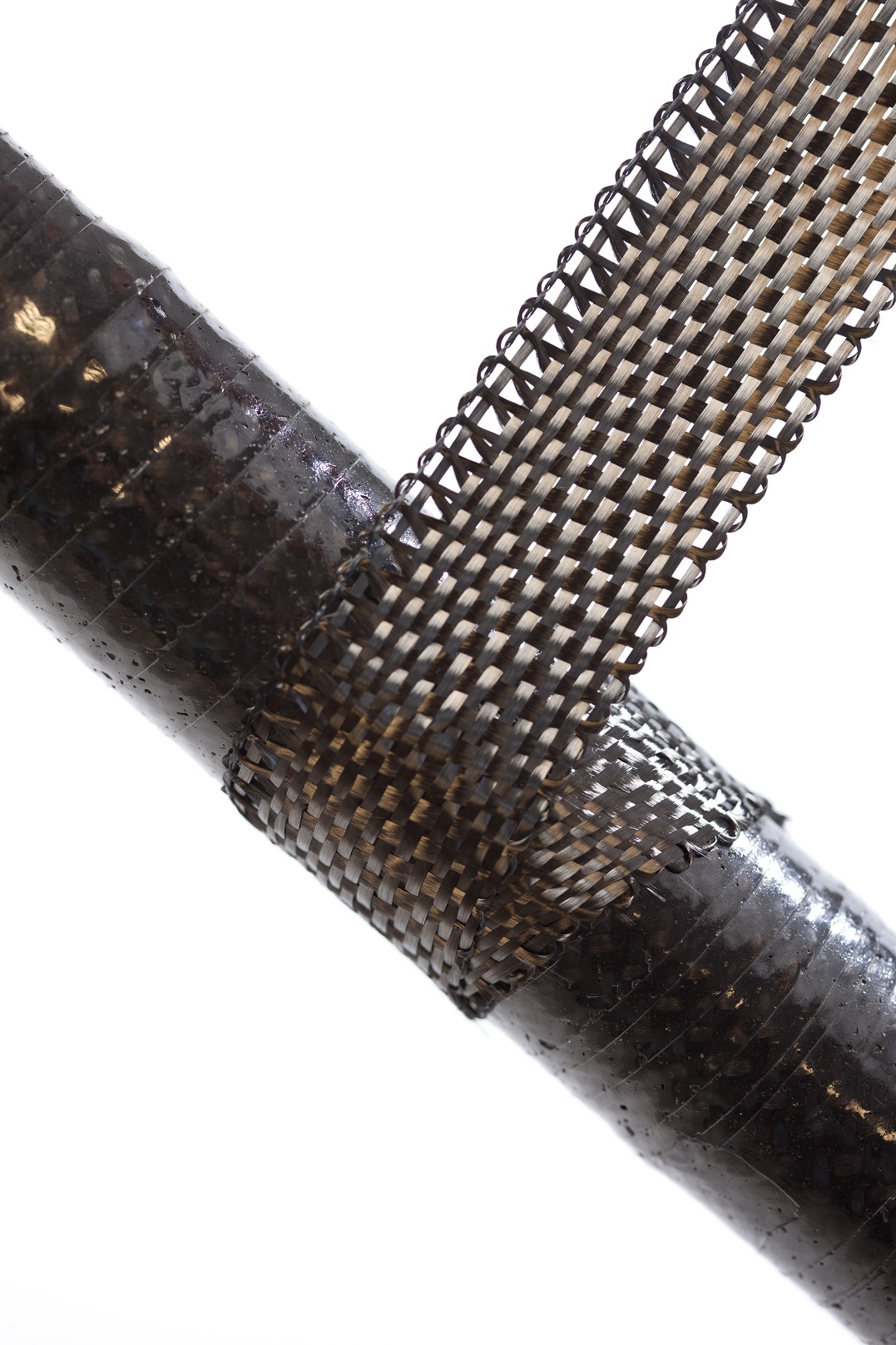

In sectors where it is important to have a good resistance to local impact, Kevlar, also better known as aramid fabric, is frequently used.

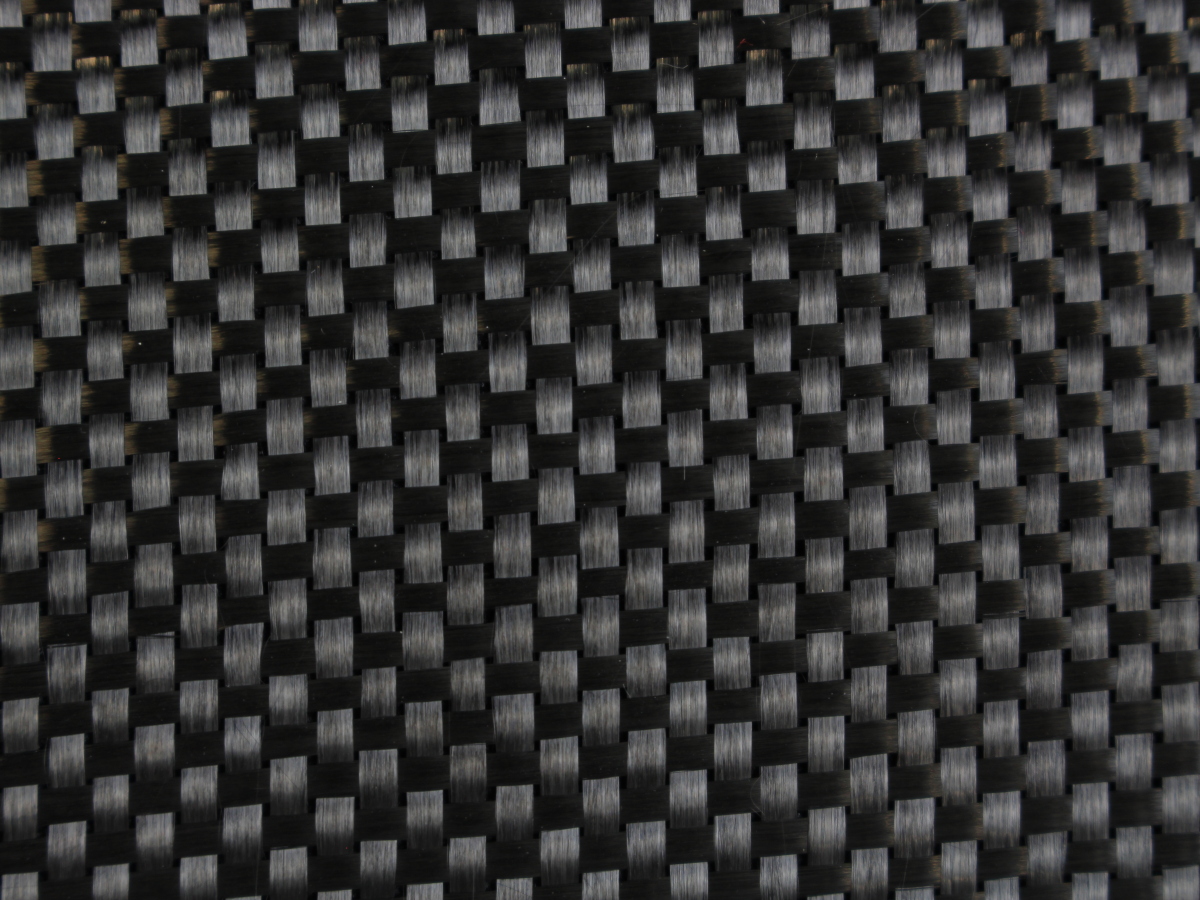

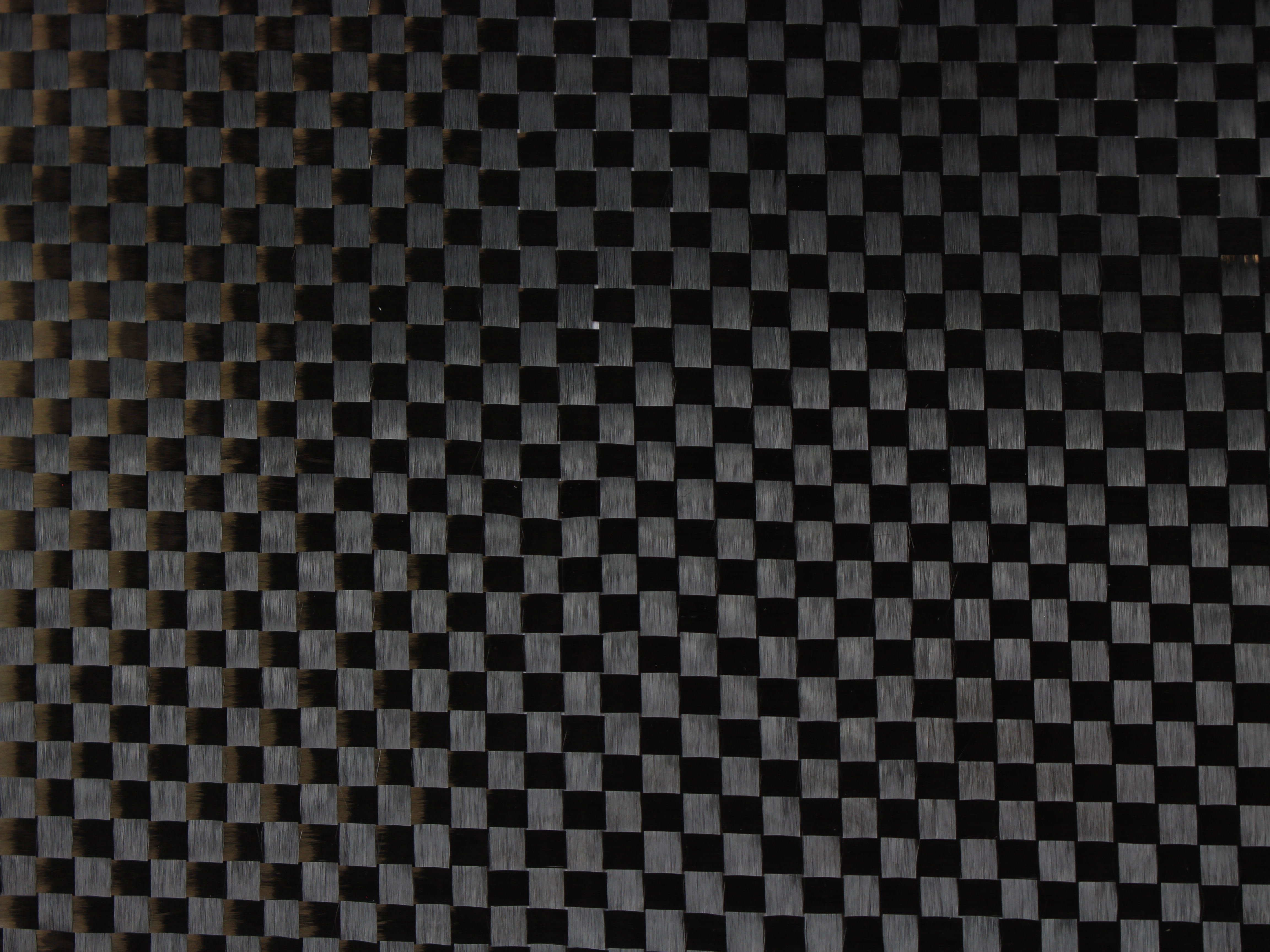

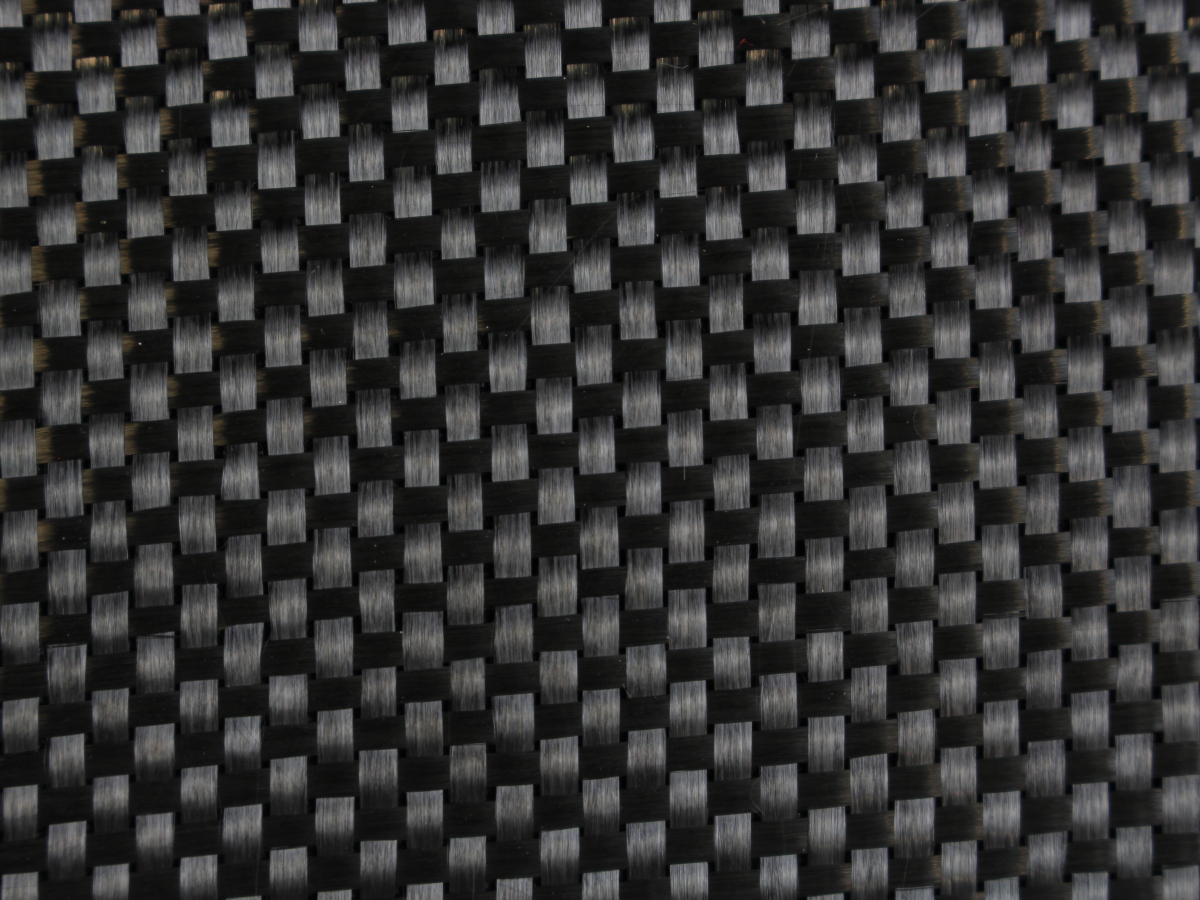

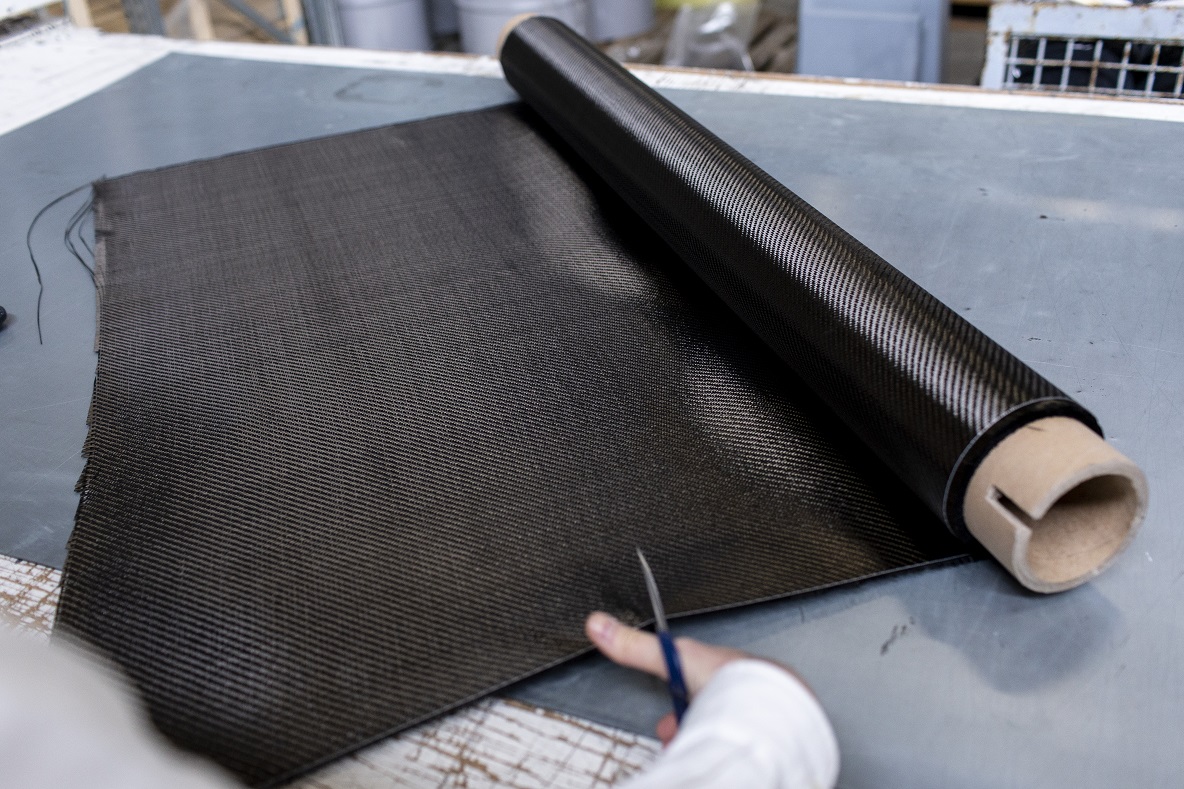

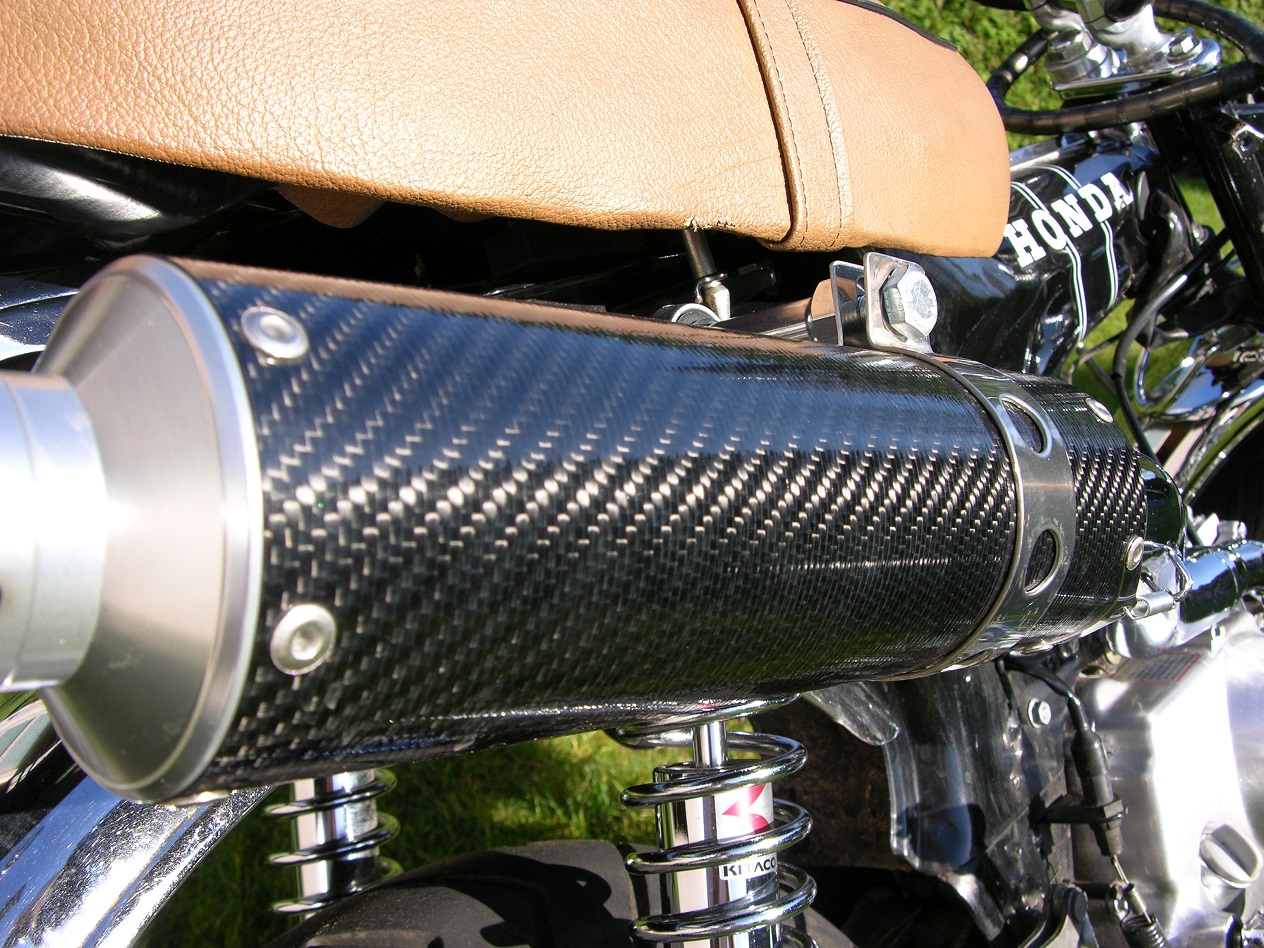

In the car industry and in the manufacture of sports articles, carbon materials are often used. These are also known as carbon fibres. These ensure a higher stiffness of the laminate.

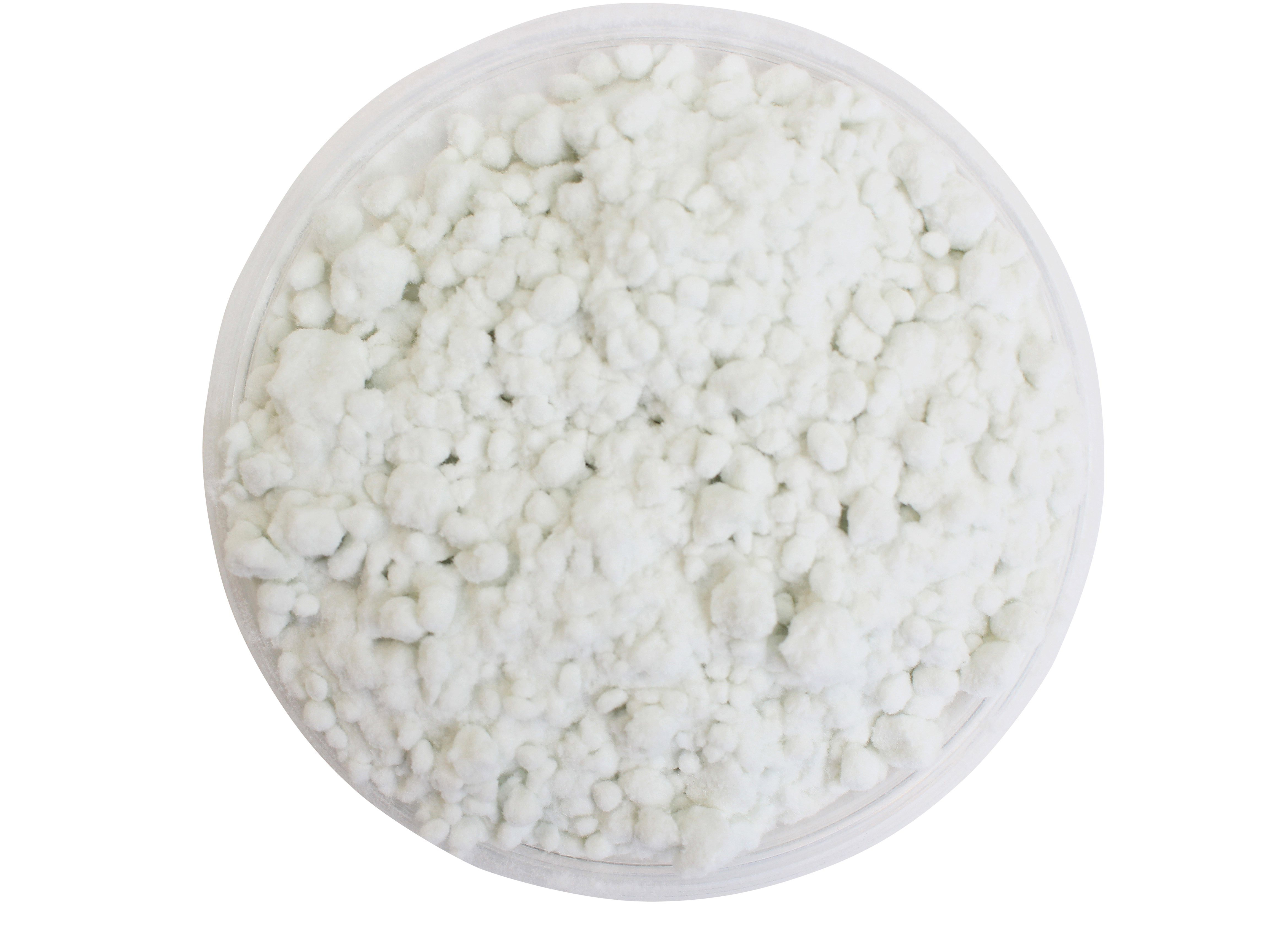

Of all the types of reinforcement materials, there is one that is used in almost every sector, namely glass fibre. This is one of the most easily handled forms of durable reinforcement material. Glass fibre is characterised by its different versions. For example, there is glass fibre in matt format known as glass mat, suitable for coating and protecting large surfaces, but also cut glass fibre for making glass fibre-reinforced putties and pastes. Furthermore, glass fibre is also available as a surface fleece, which consists of a thin layer of glass mat used to obtain a finished surface.

Natural reinforcement fibres

In recent years, more and more natural reinforcement materials have come into the picture. Linen and flax, for example, are becoming increasingly popular. These fibres can be processed in the same way as glass fibre. They have the advantage that, when applied with bio-based resins, the ecological footprint is considerably reduced.

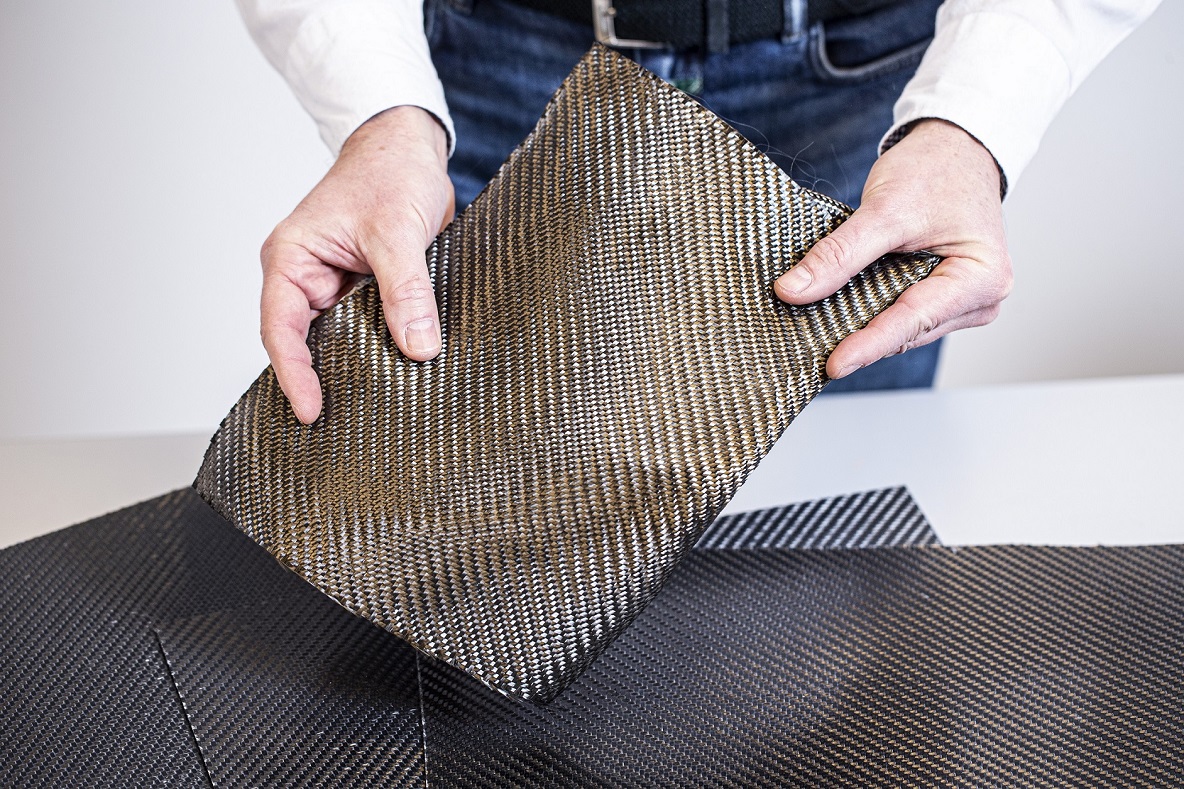

Basalt fibre is also used in applications where fire behaviour is important. This rock has a brownish colour, and in combination with fire-retardant resins has a high flame resistance.

Working with reinforcement materials

As reinforcing materials are no hazardous materials, there is no need for extra protective materials when working with them.

Summary

Benefits

- Reasonable price

- Can be combined with polyester, epoxy, vinylester

- High compressive and tensile strength

- Durable

- Wear-resistant

Disadvantages

- Limited supply of natural fibres

- Higher resin consumption for glass fibre

- Conductivity of carbon