Collect & go with online advice

Largest selection of cold curing plastics

55 years of experience

Order before 12:00, <48 hour delivery

Silicone Applications

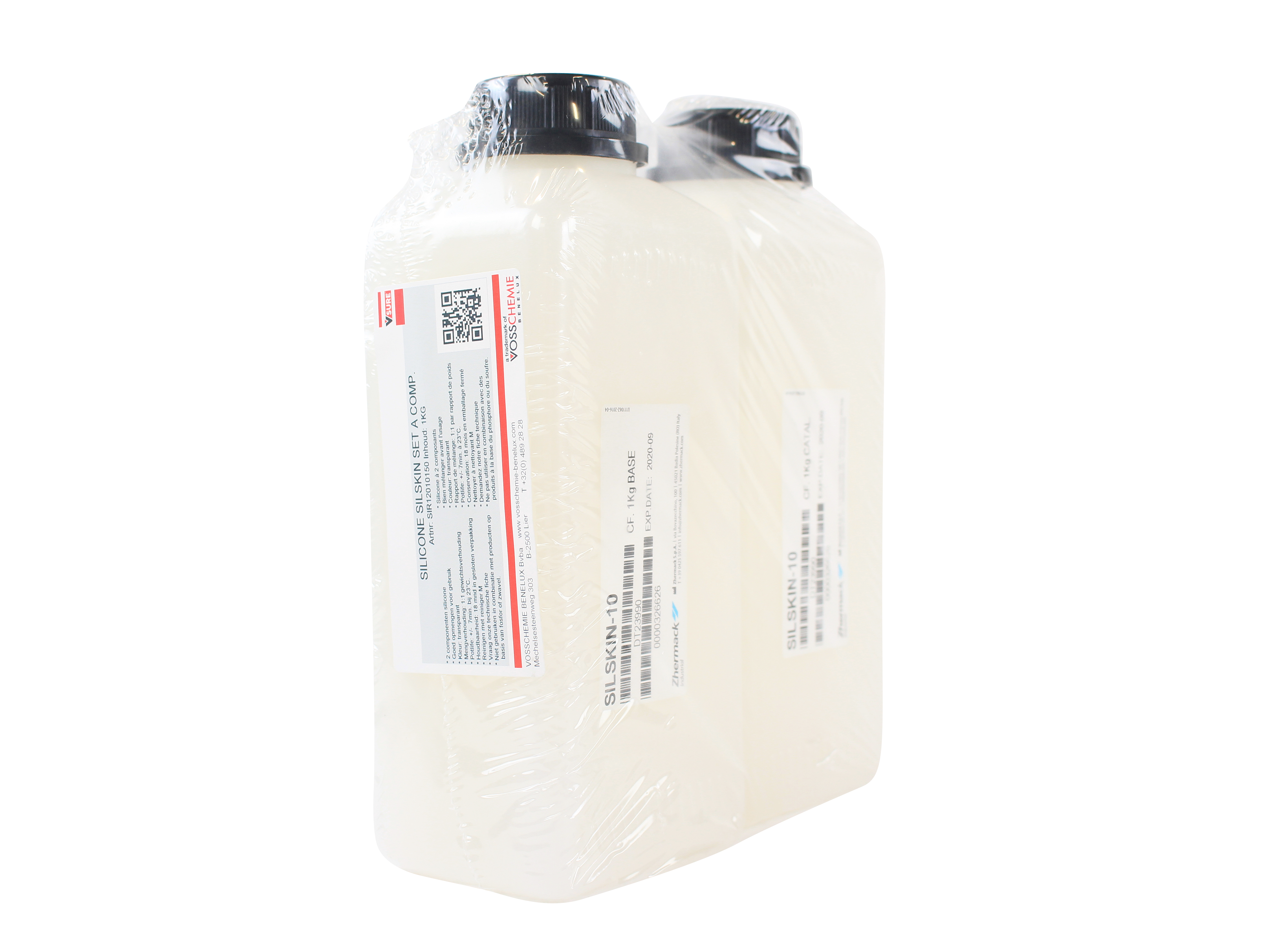

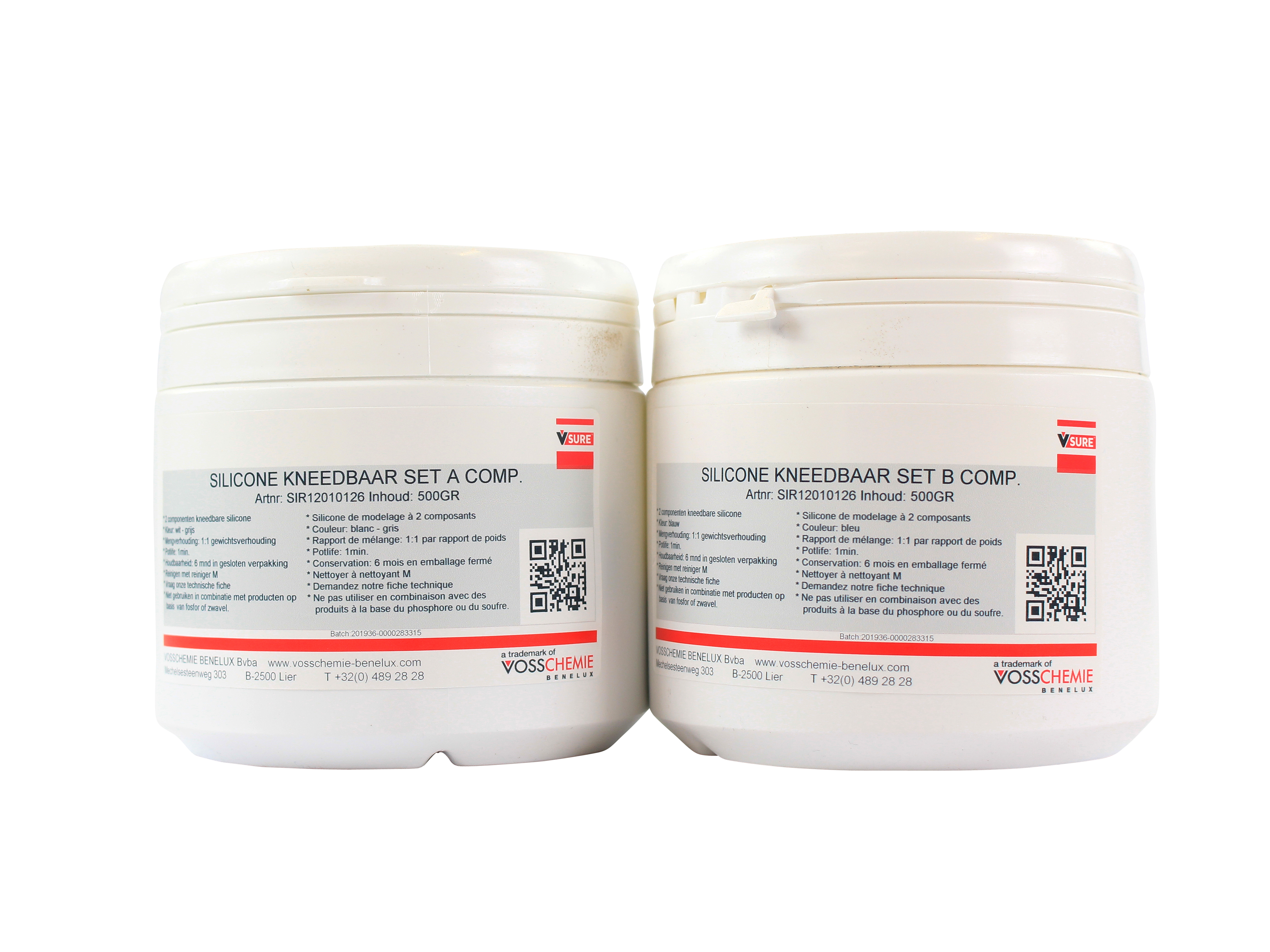

Silicone rubbers come in various types. The best known is the one-component silicone rubber. There are also rubbers made from two components. So you will always find the perfect rubber for your project.

If you intend to cast tin or lead, for example, you should use silicone rubbers that can withstand high temperatures for a short time. The single component silicone rubbers are usually used as a joint sealant or to seal seams and joints.

The range of rubbers consisting mainly of two components includes several variants of polycondensation curing rubbers. For example, there are silicone rubbers suitable for applications in the food industry, such as processing or moulding chocolate and marzipan.

In addition, it is possible to thicken the casting rubbers to make them spatterable. This is particularly useful for making peeling moulds.

Working with silicone

When working with silicone and the various additives, it is best to use personal protective equipment such as suitable protective clothing and gloves.

Summary

Benefits

- Self-dissolving

- Food-safe

- UV-resistant

- Colourfast

- Permanently elastic

- Can be coloured with pigments

Disadvantages

- Silicone only adheres to silicone

- More expensive compared to latex

- Sometimes slight shrinkage

- Cannot be glued